Newsletter #25/2024: CBAM - ACTUAL INFORMATION AND NEWS

31 July is the last regular CBAM reporting deadline for Q2 2024. This report is also the last one in which benchmarks can be used. For the Q3 2024 report, the actual emission values obtained from the manufacturer must already be reported. How to access these values? This is also the subject of today's monothematic newsletter.

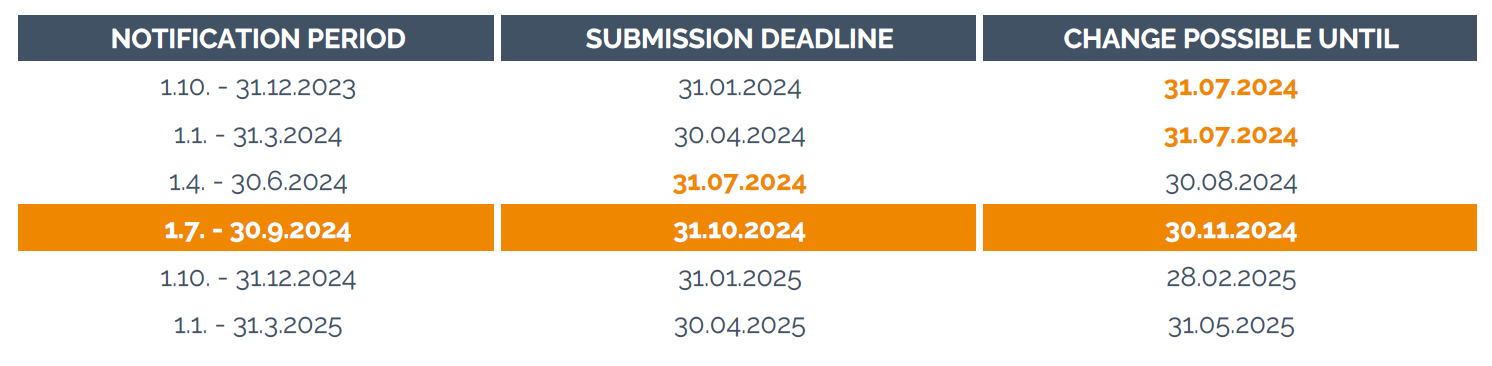

Schedule of regular reports and corrections

There are some changes and new features in the CBAM section of the European trader portal:

1) TONS only

- From Q2 2024, net mass should always be reported in tonnes (kg will no longer be selectable).

- In the case of the previous report, where the quantity was given in kg, you will need to change the net weight to tonnes.

2) Duplication of CBAM goods

- In cases where the emission information is similar for different goods that are produced in the same facility, the "Duplicate Goods" function can be used.

- The duplicated goods can be adjusted as required.

- If they result in similar scope and similar data accuracy, methods already used for third country emissions monitoring or carbon pricing may be used (but only until the end of 2024)

4) Simplification for reporting

- In cases where emissions information is similar for different commodities that are produced at the same facility, the "Duplicate Good" feature can be used. Duplicate goods can be edited as needed.

- Use of XML files to automate reporting.

- Create a message using the previous message

Probably the biggest change concerns the default values. They can be used in 100% only for imports until 30.6. 2024.

They must be used for electricity imports and for indirect emissions unless certain criteria are met. If an operator produces composite goods and purchases precursors that contribute less than 20 % of the total embodied emissions, it may use default values to determine the emissions of that precursor.

If the majority of the embodied emissions of a product are precursors (e.g. if the operator purchases steel bars for the production of bolts and nuts), the manufacturer may use default values for its own production process provided that it receives reliable data from the precursor manufacturers on their embodied emissions and that their own production process contributes no more than 20 % of the total embodied emissions.

So how do you get to the real values?

Only in cooperation with the manufacturer, of course. Basically there are 3 options, one of which is temporary:

1) By calculation - Basically, this is the determination of all fuels and input materials consumed during production, multiplied by calculation factors such as the emission factor

2) By measurement - Continuous measurement of emissions directly from the source at the plant level

3) Other - Methods already used by the facility as part of their country's emissions monitoring. Can only be used until the end of 2024

In order to obtain and exchange the necessary information, the European Commission has prepared a template, which we have shared before, but we draw your attention to its new version 2.1. of 5.6. 2024.

Do not use the earlier version!

Here you will find a link to fill in the communication template by the manufacturer. After the manufacturer fills in the information, the values are automatically calculated and transferred to the CBAM report by the declarant.

We also provide here an English version of the filling instructions, which can be sent directly to the manufacturer, either as a pdf version , or as an instructional webinar (again in English).

And what does the Ministry of the Environment and the European Commission advise you if the manufacturer does not provide you with the data?

1) Use the reference values (but only until 30 June 2024)

2) Make obtaining the emissions information a contractual condition

3) Warn the manufacturer that if he does not supply the necessary data, importers may change supplier.

4) Manufacturers to be advised that if they do not monitor their emissions, their goods will have a high carbon price in the final period (default values based on the emissions intensity of the worst facilities will be used) and will be at a financial disadvantage compared to manufacturers who monitor their emissions

And if none of this works, the EC is preparing a procedure for a situation where the importer takes all the necessary steps by the end of October and still does not receive the data from the manufacturer. This has not yet been communicated, but we believe that the solution is hidden in step 4 and therefore that the values of the "dirtiest" plants will be used, at least to start with.